| Introduction |

History | Coal Fired Power Generation Technologies |

| Pulverized Coal System |

Cyclone Furnaces |

| Environmental Impacts |

References |

Introduction:

The use of electricity has been an essential part of the U.S. economy since the turn of the century. Coal power, an established electricity source that provides vast quantities of inexpensive, reliable power has become more important as supplies of oil and natural gas diminish. In 1995, Coal burning produced about 55% of the electricity generated in the U.S. In addition,

know coal reserves are expected to last for centuries at current rates of usage.

Coal power is a rather simple process. In most coal fired power plants, chunks of coal are crushed into fine powder and are fed into a combustion unit where it is burned. Heat from the burning coal is used to generate steam that is used to spin one or more turbines to generate electricity.

History:

Coal has played a major role in electrical production since the first power

plants that were built in the United States in the1880's. The earliest power plants used hand fed wood or coal to heat a boiler and produce steam.

This steam was used in reciprocating steam engines which turned generators

to produce electricity. In 1884, the more efficient high speed steam

turbine was developed by British engineer Charles A. Parsons which replaced the use of steam engines

to generate electricity. In the 1920s, the pulverized coal firing was developed. This process brought

advantages that included a higher combustion temperature, improved thermal

efficiency and a lower requirement for excess air for combustion. In the 1940s, the cyclone furnace was developed. This new technology allowed

the combustion of poorer grade of coal with less ash production and greater

overall efficiency.

Presently, coal power is still based on the same methods started over 100 years ago, but improvements in all areas have

brought coal power to be the inexpensive power source used so widely today.

Coal Fired Power Generation Technologies:

* Pulverized Coal System :

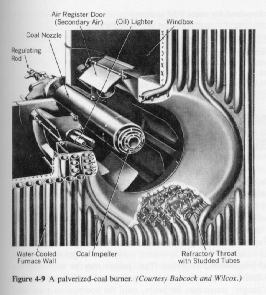

The concept of burning coal that has been pulverized into a fine powder stems from the belief that if the coal is made fine

enough, it will burn almost as easily and efficiently as a gas. The feeding rate of coal

according to the boiler demand and the amount of air available for drying and transporting the pulverized coal fuel is controlled by computers. Pieces

of coal are crushed between balls or cylindrical rollers that move between

two tracks or "races." The raw coal is then fed into the pulverizer along with air heated to about 650 degrees F from the boiler. As the coal gets

crushed by the rolling action, the hot air dries it and blows the usable fine coal powder out to be used as fuel. The powdered coal from the

pulverizer is directly blown to a burner in the boiler. The burner mixes the

powdered coal in the air suspension with additional pre-heated combustion air and forces it out of a nozzle similar in action to fuel being atomized

by a fuel injector in modern cars. Under operating conditions, there is enough heat in the combustion zone to ignite all the incoming fuel.

* Cyclone Furnaces:

Cyclone furnaces were developed after pulverized coal systems and require less processing of the coal fuel. They can burn poorer grade coals with

higher moisture contents and ash contents to 25%. The crushed coal feed is

either stored temporarily in bins or transported directly to the cyclone furnace. The furnace is basically a large cylinder jacketed with water pipes

that absorb the some of the heat to make steam and protect the burner itself

from melting down. A high powered fan blows the heated air and chunks of coal into one end of the cylinder. At the same time additional heated

combustion air is injected along the curved surface of the cylinder causing

the coal and air mixture to swirl in a centrifugal "cyclone" motion. The whirling of the

air and coal enhances the burning properties producing high heat densities (about 4700 to 8300kW/m2) and high combustion temperatures.

The hot combustion gases leave the other end of the cylinder and enter the

boiler to heat the water filled pipes and produce steam. Like in the pulverized coal burning process, all the fuel that enters the cyclone burns

when injected once the furnace is at its operating temperature. Some slag remains on the walls insulating the burner and directing the heat into the

boiler while the rest drains through a trench in the bottom to a collection

tank where it is solidified and disposed of. This ability to collect ash is

the biggest advantage of the cyclone furnace burning process. Only 40% of the ash leaves with the exhaust gases

compared with 80% for pulverized coal burning. Cyclone furnaces are not without disadvantages. The coal used must

have a relatively low sulfur content in order for most of the ash to melt for collection. In addition, high power fans are required to

move the larger coal pieces and air forcefully through the furnace, and more nitrogen oxide

pollutants are produced compared with pulverized coal combustion. Finally,

the actual burner requires yearly replacement of its liners due to the erosion caused

by the high velocity of the coal.

Environmental Impacts:

Please

Note:

IECG

and International Electric hold in dispute many of the commonly held

concepts about the environmental impacts of coal fired electrical

generation. We believe that the benefits far outweigh any potential

negative impacts. IECG and CRPG work with the community and with

recognized experts to minimize and eliminate any potential environments

hazards such as:

* Coal mining causes severe erosion, resulting in the leaching of toxic chemicals into nearby streams and aquifers, and

destroys habitants.

* About two-thirds of sulfur dioxide, one-third of carbon dioxide emissions and one quarter of the nitrogen oxides emissions in the U.S. are

produced by coal burning.

* Coal burning also results in the emission of fine particles matter into the

atmosphere. Nitrogen oxide and fine airborne particles exacerbate asthma, reduce lung function and cause respiratory diseases and premature

death for many thousands of Americans.

* Smog formed by nitrogen oxide and reactive organic gases causes crop, forest and property damage. Sulfur dioxide and nitrogen oxides both

combine with water in the atmosphere to create acid rain. Acid rain acidifies the soils and water killing off plants, fish, and the animals that

depend on them.

* Global warming is mainly caused by carbon dioxide emissions and is responsible for at least half of the warming.

References:

http://starfire.ne.uiuc.edu/~ne201/1996/kawka/conc.html-Conclusion

http://starfire.ne.uiuc.edu/~ne201/1996/kawka/tech.html-Current technology

http://starfire.ne.uiuc.edu/~ne201/1996/kawka/history.html-History and

Background

http://www.geology.utoledo.edu/programs/courses/2020/MN/c.htm-Coal

http://www.utilityguide.com/1common/coal.html-Utility Guide Coal

| Top

|

| Home

|

| IEGC In The News |